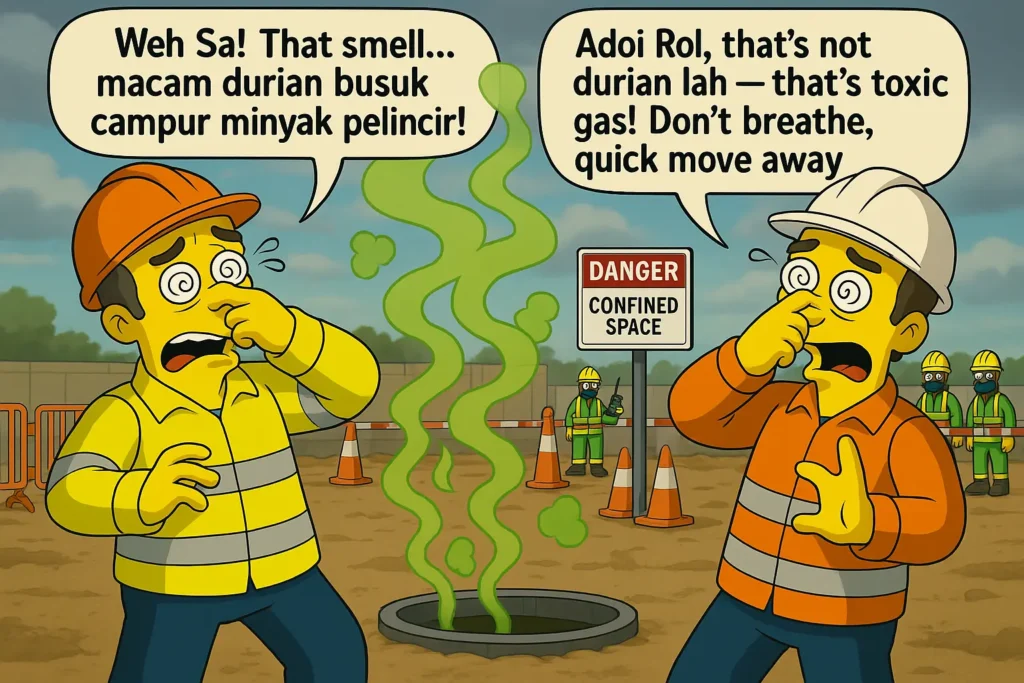

A confined space may look harmless, but they’re one of the most dangerous places to work. Poor air, toxic gases, and limited exits can quickly turn deadly if safety procedures are ignored.

What Is a Confined Space?

A confined space is an area large enough for a person to enter and perform work, but with limited entry or exit points, and not designed for continuous occupancy.

The risks in such environments are extremely high. Confined space work is considered one of the most hazardous activities under safety and health management. That is why DOSH has produced Industry Code of Practice for Safe Working in Confined Space, 2010

Common Examples of Confined Spaces

- Tanks or vessels

- Pipes and ducts

- Sewers or drainage systems

- Hoppers and bunkers

- Manholes or pits deeper than 1.5 metres

- Silos, tunnels, or underground chambers

- Air-tight or high-pressure rooms

- Cold storage rooms

Confined spaces exist in almost every industry, not only in oil and gas. They appear anywhere from construction sites to factories, water treatment plants, or even warehouses.

Why Confined Space Work Is So Dangerous

Many workers around the world have been seriously injured or killed while working in confined spaces. The main causes include:

- Lack of oxygen (asphyxiation)

- Inhalation of toxic gases or fumes

- Fire or explosion due to gas accumulation

- Structural collapse or soil failure

- Sudden temperature rise or heat stress

Rescue in confined spaces is often difficult because the conditions are unpredictable, and rescuers themselves face high risks.

Key Safety Aspects to Consider

Before starting any confined space work, the following must be checked and controlled:

- Personal Protective Equipment (PPE) – Ensure the right gear such as breathing apparatus, harness, gloves, and gas detectors.

- Emergency Response Training – All workers must know how to act quickly and safely in emergencies.

- Access Control – Provide safe entry and exit routes with proper supervision.

- Permit-to-Work System – Never enter a confined space without a valid permit approved by a competent person.

- Atmospheric Testing – Test for oxygen level, flammable gases, and toxic substances before and during work.

- Health Condition of Workers – Only medically fit workers should be assigned to this task.

- Communication – Maintain constant contact between workers inside and the attendant outside.

- Isolation and Lock-Out – Disconnect energy sources or pipelines before entry.

- Documentation and Records – Keep inspection logs, calibration records, and training certificates.

- Rescue Plan – Ensure standby rescue teams are equipped and ready before work begins.

Lesson Learned

Confined space accidents are almost always preventable. They happen not because the space is dangerous by nature, but because people take shortcuts or skip safety checks.

Employers must stay committed to safety by ensuring every entry is properly planned, authorised, and supervised. When safety comes first, confined space work can be done safely and efficiently, without tragedy.